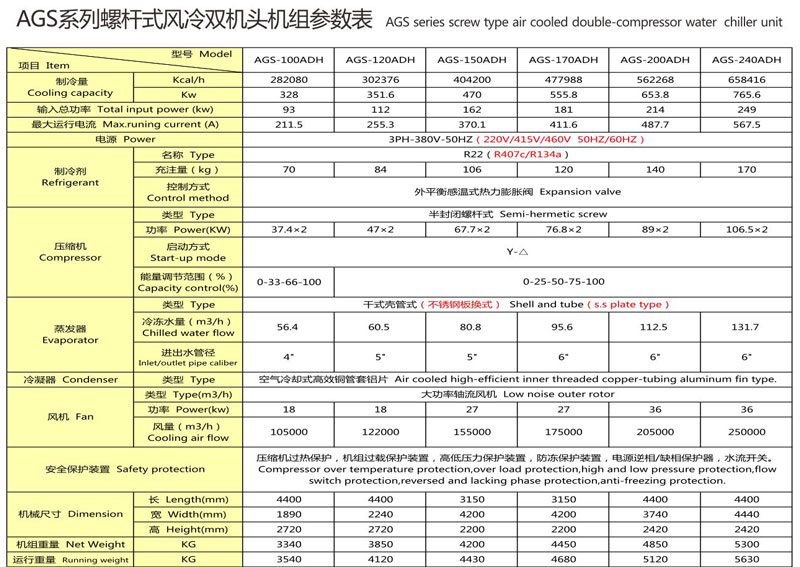

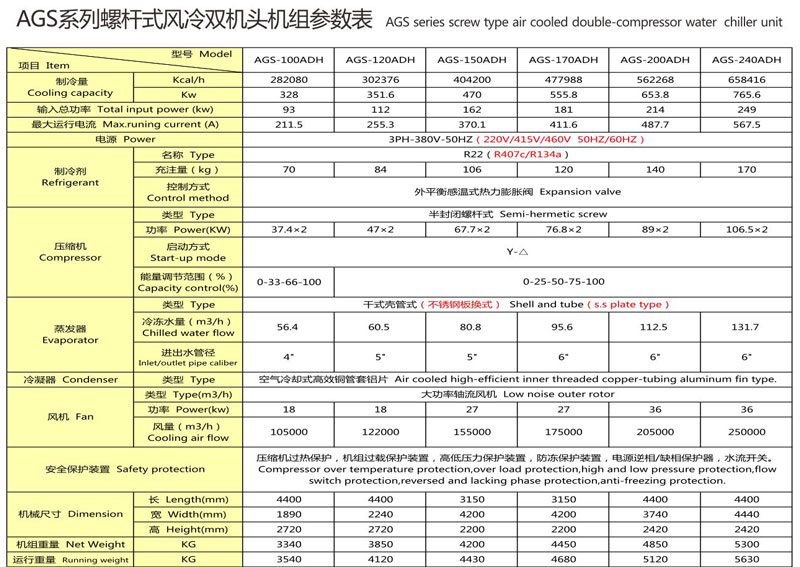

Industrial Air Cooled Chiller Units Machine AGS-200ADH

Details

Industrial air cooled chiller units machine use the world famous brand new type and high-efficient screw-rotor compressor,with efficiency 20%-30% higher than those common ones.It has obtained several patents of Europe and America countries and passed the international quality certification of ISO9001.

Simple structure, stable quality and high heat transfer performance.

The condenser of the air cooled chiller unit is made of aluminum fins and row column tubes to guarantee the high efficiency of heat exchanger.

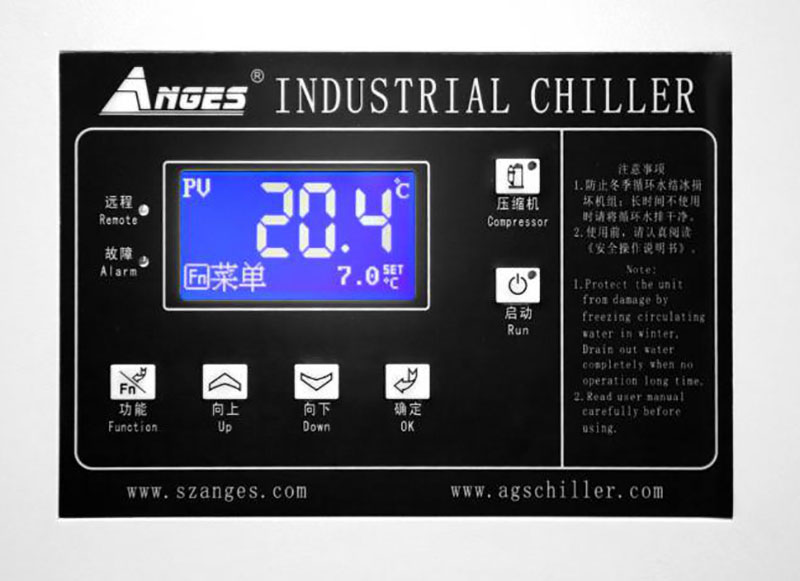

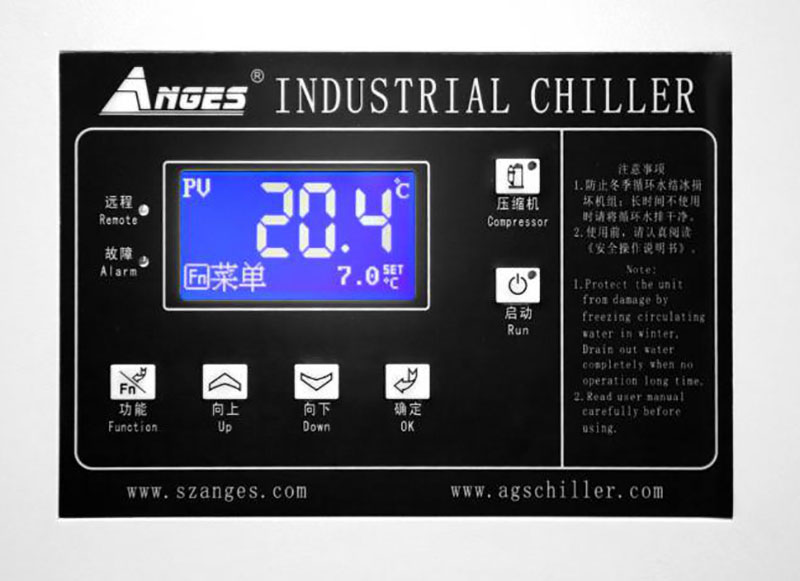

Precise digital display temperature controller is provided to precisely control water temperature with variation of ±1℃.Temperature can be set in the range from 5℃ to 35℃.

Stainless steel water pump featuring wide working range, low noise, reliable performance.

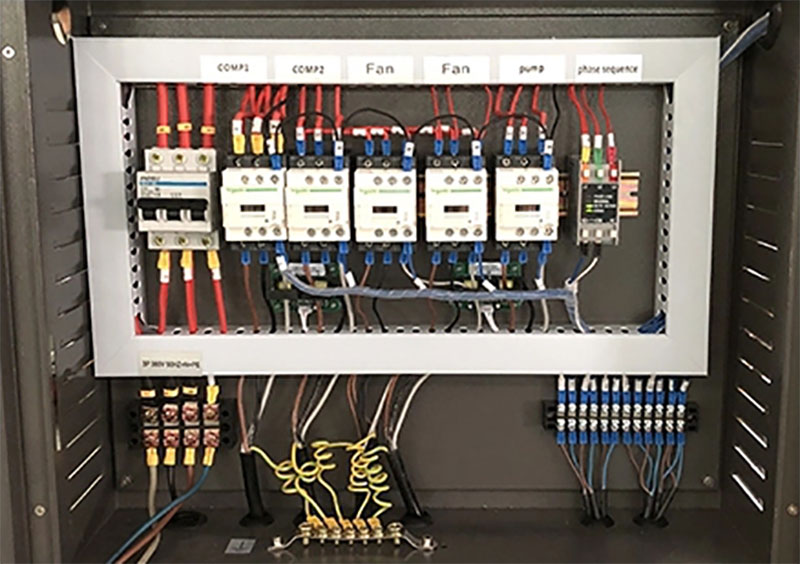

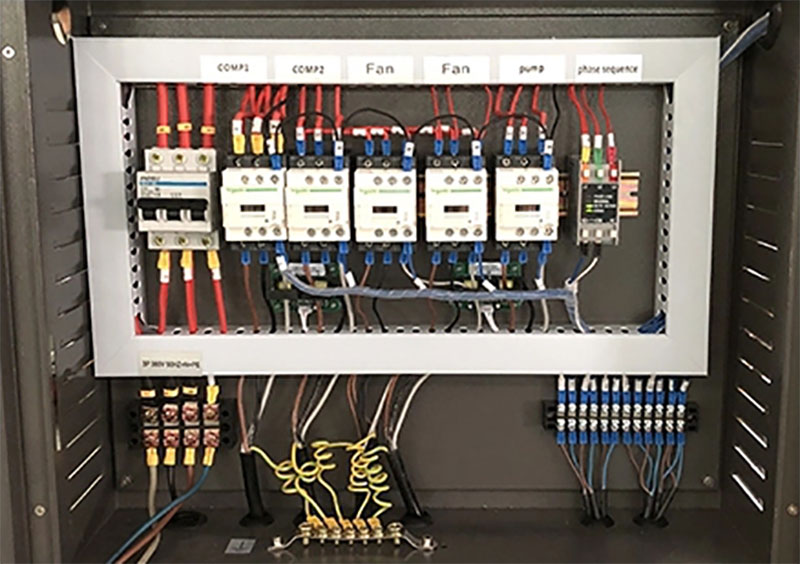

Safety features, such as phase failure protection, flow switch protection, high and low pressure protection and over-heating protection. Higher reliability, low breakdown rate and perfect service system.

Redesign the route of the pipes and fix the pipes to prevent refrigerant leakage caused by vibration.

Environment-friendly refrigerant R407C, R410A, R134a, etc, which is no harm to the ozone layer.

All products of Air-cooled Screw Chillers Series

Why choose us?

1.Anges has passed the ISO9001 international quality system certification, also many products have got the CE certification.

2.Anges currently has several independent research patents.

3.we also have many agents in Indonesia, Thailand,and other countries, to fully ensure that every user to enjoy a high quality after-sale service when they using Anges products.

Company Information:

Shenzhen Anges Machinery Co., Ltd is located in the forefront of China's reform and opening up city-Shenzhen. Since it founded in 2004,it always adhere the idea of "Let's freeze the industry”, Anges has developed into the word's leading industrial refrigerate equipment supplier.

FAQ:

Q:How do you maintain a chiller system?

1.Keep a daily log.

2.Keep tubes clean for efficient heat transfer.

3.Treat condenser water to prevent scale, corrosion.

4.Lower entering water temperature.

5.Keep chilled water flow rate between 3 to 12-ft per second.

6.Maintain adequate refrigerant charge.

7.Prevent inefficiencies caused by non-condensables.

Q:How do condensers and evaporators work?

The evaporator works the opposite of the condenser, here refrigerant liquid is converted to gas, absorbing heat from the air in the compartment. When the liquid refrigerant reaches the evaporator its pressure has been reduced, dissipating its heat content and making it much cooler than the fan air flowing around it.

Q:What types of compressors are typically installed on water chillers?

Water chillers use scroll,screw, reciprocating, rotary or centrifugal compressors.

Reciprocating, scroll, or rotary helical compressors are used in smaller machines.

Q:How do condensers and evaporators work?

The evaporator works the opposite of the condenser, here refrigerant liquid is converted to gas, absorbing heat from the air in the compartment. When the liquid refrigerant reaches the evaporator its pressure has been reduced, dissipating its heat content and making it much cooler than the fan air flowing around it.

online service

online service